Mercedes E240 - Headlamp Restoration and Paintwork Enhancement

Good day folks!

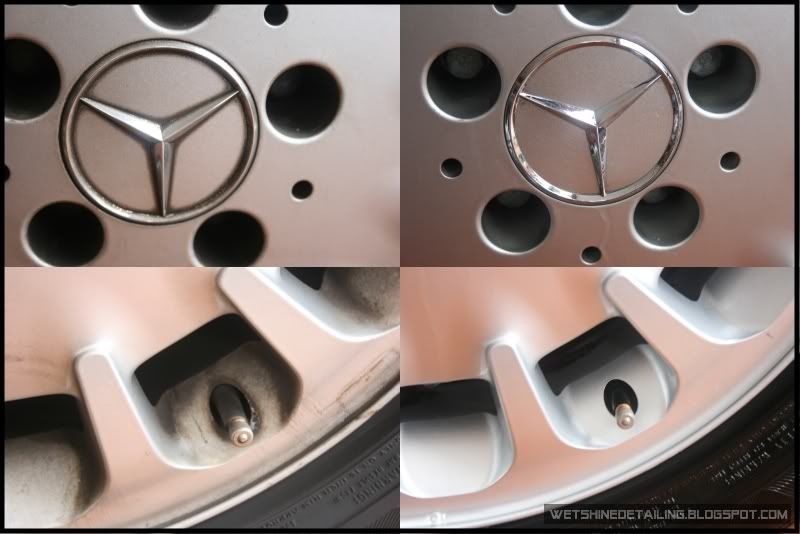

Just recently detailed a Mercedes E240 that was in for two days. Wish I had more time as there was many things could be done to improve the state of the car. This car has never polished for three years and always washed at petrol station car washes. So there was a lot of grime buildup at the corners of the wheel.

The headlamps were also severely oxidized as there was cracking and blistering in the plastic, it was restored with machine and hand sanding, followed by machine compounding and polishing. Paintwork was also given a 'quick' polishing with the M105/M205 combo.

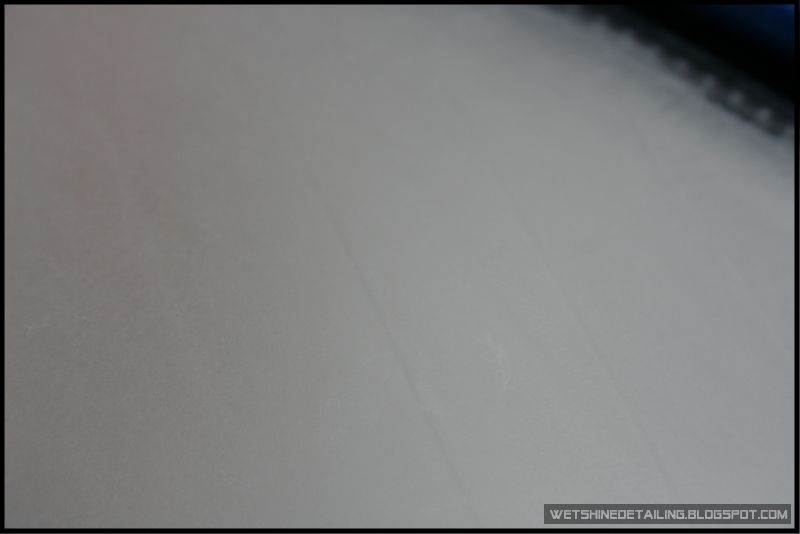

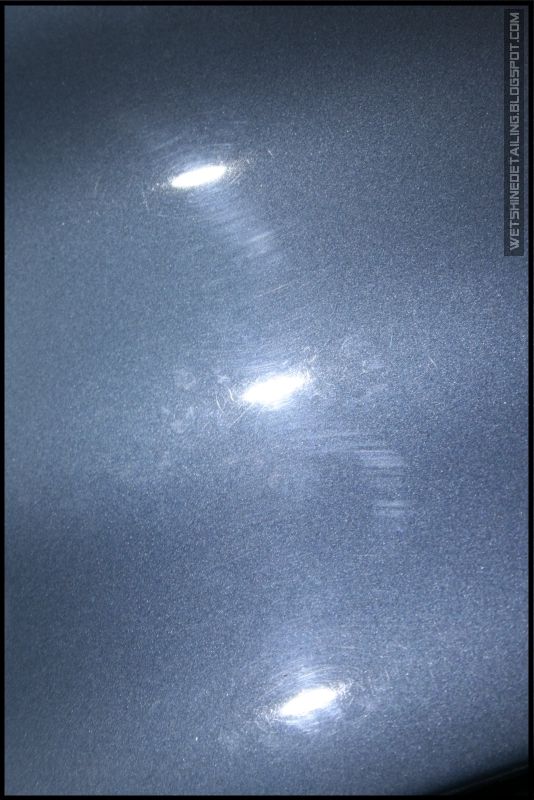

Although the car was clean to start with, it was in a pretty bad condition. The paintwork has water spots, moderate swirling and this gave it a hazy look to the whole car. This is how the car looks before doing anything.

So I began by cleaning the wheels, wheel wells and tires first. I spent a little too much time here and the results were also less than perfect, wish I had a polishing tool to get the wheel totally clean.

Tires were cleaned with Westley's Bleche White. Wheels cleaned with Carmate PS60 Brake Dust Cleaner. Cotton buds were used to get in the little small holes.

With the wheels out of the way, it was time to clean the bodywork. The car is foamed with a mixture of Osren Nano Wash(200ml) and Osren Multi Clean(150ml) diluted in a one litre bottle. As the foam was dwelling, I went around the car with some Meguiar's All Purpose Cleaner and a brush to clean tight areas such as window rubber trims, door mouldings, and panel gaps.

I then washed the car with a very light mixture of Chemical Guy's Citrus Wash and Gloss. Paintwork smoothened with Osren Magic Clay Cloth.

I then had a quick Chinese lunch, glutinous rice with chicken!

With the whole car fully clean, I turned my attention to restoring the headlamps first. I've never done this before but after reading some work examples and product descriptions of the net, you'll get the general idea.

The right side is after sanding, compounding and polishing.

Tools and products used:

Bosch GEX270-AE

Makita 9227C

Foam interface

Bosch 400 grit Random Orbital sanding discs

Generic sandpapers(600,800,1000,1200,1500,2000 grit)

Mirka 2000 grit sanding discs.

Meguiar's sanding backing pad.

Lake Country 3.5" Purple Foamed Wool

Lake Country 4" Orange CCS pad

Lake Country 4" White CCS pad

Meguiar's #105 Ultra Cut Compound

Meguiar's #205 Ultra Finishing Polish

A bottle of clean water and another bottle with diluted Presta Lubri-Sudzz.

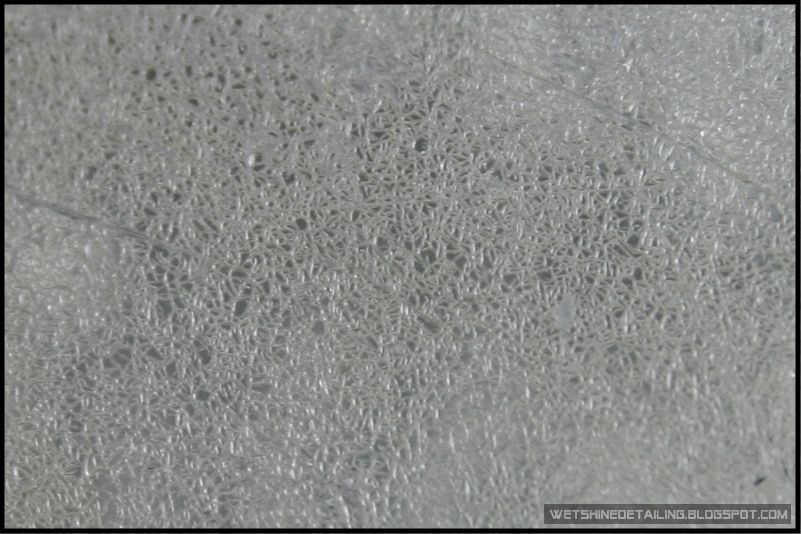

Here's the condition of the headlamps before doing anything.

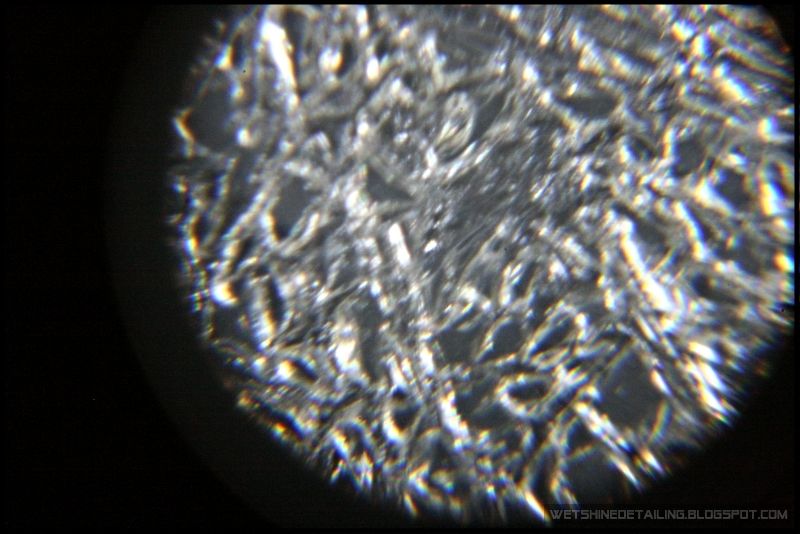

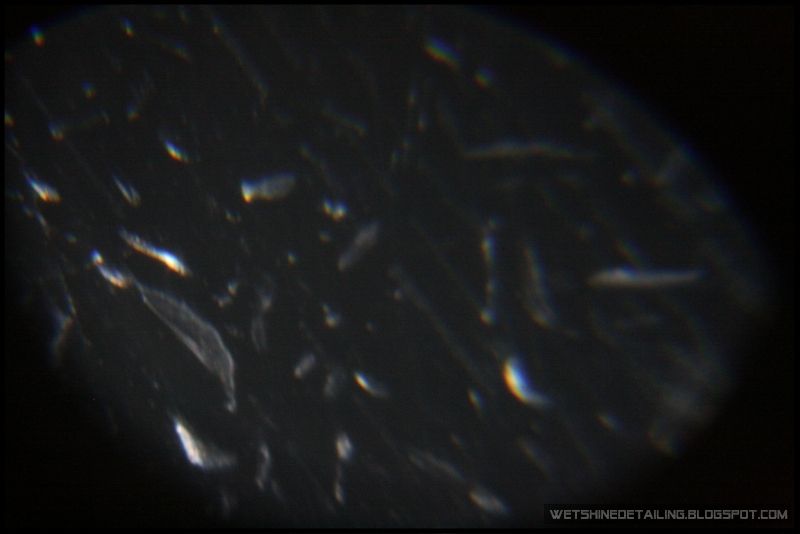

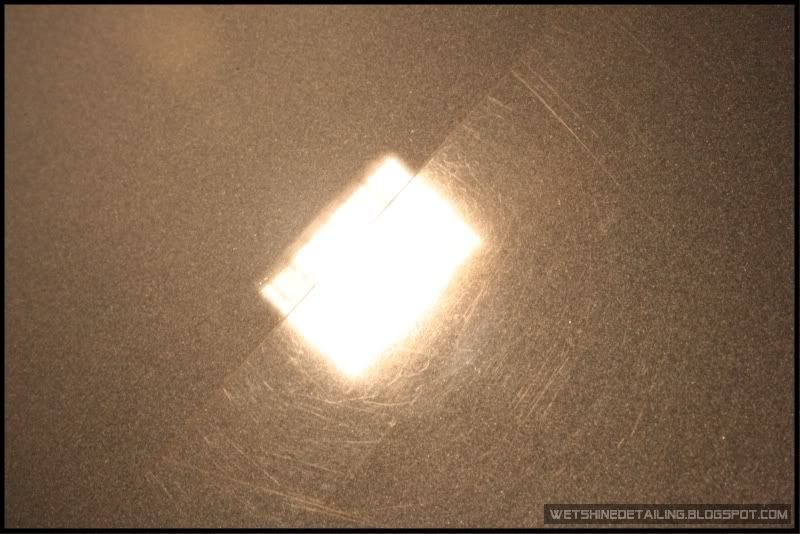

I then looked at under a magnifier.

I tried to capture what I saw with the camera, sorry if it's really blur, but you can see that the plastic has tiny cracks and blisters all over the surface.

So the objective is to remove the top layer of blistering and to restore the clarity to the plastic.

I started with sanding it down with a Bosch 400 grit sanding disc.

After every pass, I flush the headlamps with water and squeegee the lamps with a Meguiar's sanding backing pad to check my progress.

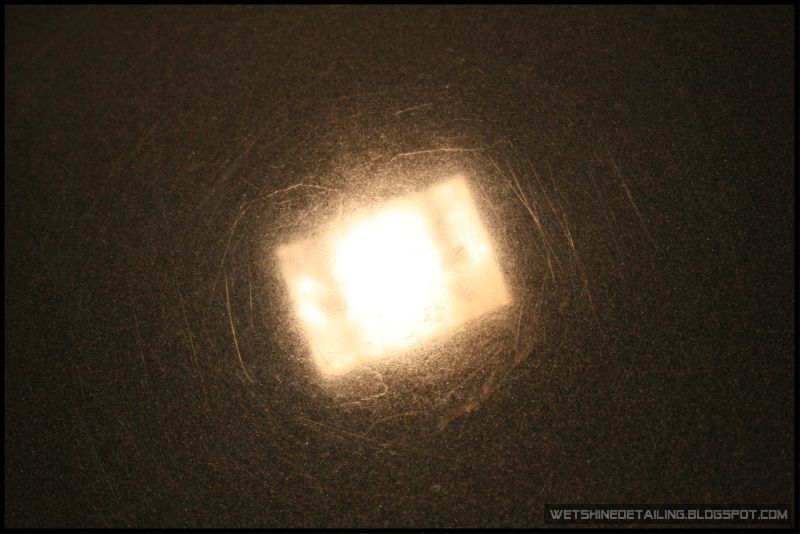

I sanded until I cannot feel the cracks or blisters on the plastic. The headlamps will have a uniform frosted glass look.

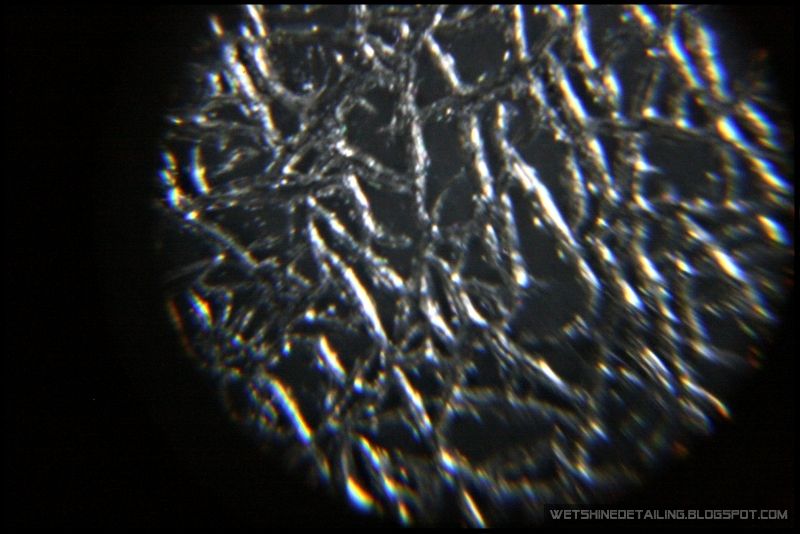

This is what it looks like up close and under the magnifier.

Also, don't forget to wear some eye protection as it can get a little messy.

Since I didn't have finer sanding discs, I resorted to hand sanding. Starting from 600 grit and working my way through finer grits, 800, 1000, 1200, 1500 and 2000.

After hand sanding with 2000 grit.

The last sanding stage is done with Mirka 2000 sanding disc, I cut them out to fit on to my foam interface. Thanks to dschia for the tip!! This step is to try to sand away all hand sanding marks.

And you can see the haziness start to clear up after sanding with the Mirka disc.

I really love the disc and can see how gentle they can be when used for paintwork. The 2000 grit disc was also still not strong enough to quickly remove the hand sanding marks from the headlamps. So many passes were needed.

After that, I followed up with some M105 on purple foam wool and orange CCS pad. Then M205 with a white CCS pad for greater clarity. The lamps are protected with some Meguiar's PlastX, applied on like a wax instead of rubbing it in like a polish.

Buffed off and ta-da!!!

Up close,

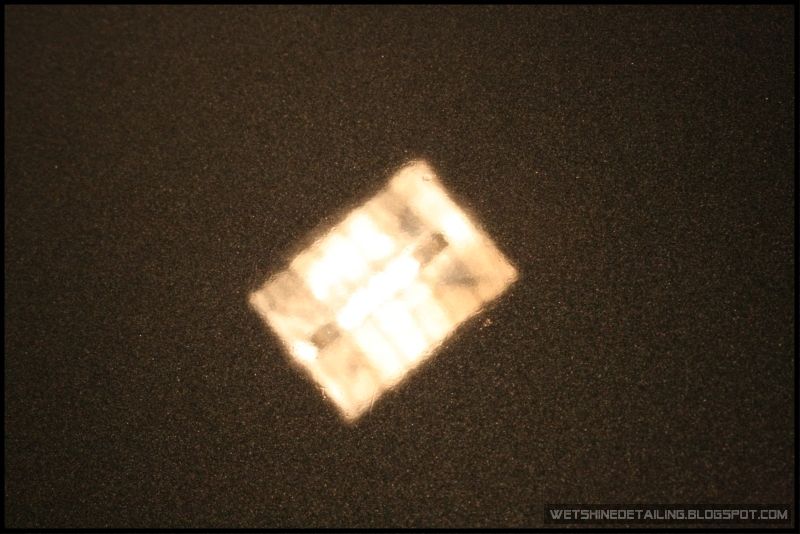

Under the magnifier,

On the edge of the lamps, it wasn't perfect as I didn't feel comfortable sanding with a large disc near the painted surface, even though they were masked.

Before,

After,

With the headlamps done, I turned to the paintwork.

The process for the boot lid was:

M105/Lake Country 4ply twisted wool/1500 rpm

M105/Lake Country White Kompressor pad/900-1500 rpm

M205/Lake Country flat black pad/900 rpm

Before,

After,

50/50,

The rest of the paintwork received:

M105/Lake Country White Kompressor pad/900-1500 rpm

M205/Lake Country flat black pad/900 rpm

Before,

After,

Before,

After,

One thing bad about the Kompressor pads is that when they are freshly loaded with polish, the 'flaps' on the pad will have a greater tendency to leave polish in the panel gaps.

I was behind time at this point so didn't take much pictures of the correction process. It wasn't a full correction work but I tried to get rid of as many defects as possible. After polishing, the car was foamed with Presta Lubri-Sudzz to help dissolve polish residue in the cracks and then pressure washed away.

For the interior, leather seats were cleaned with Meguiar's Step 1 Aloe Leather Cleaner diluted with water and scrubbed with a nail brush. Plastic and vinyl wiped down with Meguiars Quik Interior Detailer, glass cleaned with Meguiar's Detailer line glass cleaner.

50/50

Dirt from the seats.

Paintwork was protected with the Werkstatt twins.

Dirt pulled out from the paint and surrounding rubber trim during the Prime:Acrylic process.

Tires dressed with Osren Tire Shine. Wheel wells with Meguiar's Hyper Dressing and mudguards with Autoglym Bumper Care.

Enjoy the pictures!

Many things could still be done, such as removing watermarks from the glass and polishing the wheels as they were not totally clean during the washing process. More time on the paintwork could also be beneficial.

Anyway, for the time given, I was happy with the results!

Thanks for looking!

Oh just a special mention of a few friends that also blog about their work if you haven't visited their blogs before in my list of links below.

My friend from Singapore does paintwork correction work and achieves great results...in a petrol station! Many people have the perception that petrol station car washes or polishing services are generally rubbish, but not Golden Wax - Shine My Car detailing. Some detailers have nice polishing studios to polish their cars in but he has to work in a less than desirable condition and environment, but still produce great results! Check out his blog at http://smcgoldenwax.blogspot.com/

Known as the super Malaysian Duo on the Meguiar's Online Forum, both KC and Seech detail on a part time basis.

KC is known for his super human polishing speed, detailing 4 cars in a day and his hand can wax a car faster than an orbital buffer! He only started detailing eight months ago but has detailed over a hundred cars, including Porsches and Ferraris!

Check out his work on his blog at http://thedetailers.blogspot.com/

Seech is known for his Porsche 911 Turbo Special Martini edition detail, where he sanded down the paint to reveal its true luster. Talk about courage! The detail was also featured in Meguiar's Online Newsletter. You just have to read that thread. Visit his detailing blog at http://prodetailing.blogspot.com/

19 comments:

Awesome job dude!

Must have been very very hard work, and tiring too.

loh mai gai??!!

yum!

@jackson,

Thanks mate! Well I didn't aimed for perfection on the paintwork, so I could slack a bit, haha. Even so, you are right about it being tiring... leg and arm muscles hurt for a day.

@Jun,

WOW! You know what is that?! PRO!

Oh wow.. if it took you that long to do the merc, I wonder how long it'll take you to do my dad's unser who's probably in worse wear than this Merc. LOL

Nice job as usual dude!

And it's Porsche, not Porches. :P

Izso,

Why do you want it detailed? It's an Unser! Haha joking man, if I got time I let you know, will turn it into the most bling Unser in Malaysia.**

Haha thanks for spotting that typo... Porches, LOL.

**Actual results may vary from the pre-detail exaggerated statement.

That's a LOT of expensive blue masking tape!!!!

Amazing amount of work done on the headlamps..... I'm speechless...

super man at work

awesome work there

yr post never fail to impress me...absolutely astounding

ma ma mia buddy

@Seech,

Haha, that's the Ace Hardware brand tape. The normal masking tape was thin and I worry will sand through it if I go over the edge, hence the thicker blue tape.

Thanks for your compliments!

@KC,

Thanks KC, ma ma mia!!

nice.....haircut...ha ha

Limbiscuit,

Thanks, but I'm starting to hate it, haha!

hi

Hi

Nice work!

I've been restoring headlights with 3M stuff for some time now, check it out.

http://solutions.3m.com/wps/portal/3M/en_US/3MAutomotive/Aftermarket/Products/Featured_Products/Headlight/

Keep up the good work!

Haha finally learn how to post comment to blog.

Good afford fish and glad to see u finally used the brush to clean leather. So u did not managed to find the Horse hair soft brush that I mentioned which I think are gentler to softer type of leather, but these type and the Kiwi brush (RM4.5) does clean faster. pls allow me to chip a few about your headlamp restoration.

From wht I see from your photos, did you try compounding first instead of sanding because I think the conditions are not extremely severe but I am not 100% sure since only viewing from web. The DG plastic polish can remove the yellowish, haziness and some fine marring but not crack.

Secondly, did u try 1500 grit first instead of 400? I think it’s a bit too harsh for plastic headlamp. Also did u try refining it with 1000 or 1500 grit after your 400 because it seems too many steps and every steps of sanding , your headlamp will be thinner? Haha Dunno man~ , For very severe headlamp, the lowest I dare to go will be 1000 -> 2000->3000-(by hand)> compound-> polish-> sealant.

3rd, I think ROB are not so safe for headlamp sanding since the backing is almost 5”, a 3 to 3.5” will be more suitable.

4th, I think u might have mist too much water on the disc when I saw your specs, remember our sanding session at Osren which I only mist with 1 to 2 light pump. The Mirka 1500 does cut well if not too much of water and you can refine it further with 3M Trizact 3000 or Mirka Abralon 4000…this will ease your next compound process. Remember we only need about 1 to 2 round of compounding to remove all sanding marks and pigment tails after the 3000 grit.

Lastly, just a gentle advice.pls advice the owner to apply some sealant protects frequently after this sanding process and I always enjoy reading your blog.

Cheers and take care.

p/s: your new hair style …Err.. I like your previous better. Haha

@222,

Thanks for your comment and for pointing out the 3M products that you use.

@mubull,

Thanks for your long and elaborate comment!!

Firstly, no I didn't try compounding first because if you can feel what I felt on the headlamps that day, I think you will jump to sanding straight away also, haha. It fees really rough.

I actually didn't start from 400 grit first, but start with the Mirka 2000 grit disc. It was working nicely and managed to get the headlamp pretty clear but the surface still feels rough and many cracks and blisters can be seen under the magnifier. I gave it many passes also it wouldn't cut the level of cracks away, I got fed up until the point that I used the Mirka 2000 grit disc with a rotary. Yes I remembered your demo on sanding paintwork. I also used very little water but 2000 grit just wasn't cutting it(pun intended). I hand sand with 1500 grit and was making better progress, but still too slow for my liking. It was a two day detail and I haven't even worked on the paint after the first day. So the next morning I went to ACE hardware and purchased the finest sanding disc available, the Bosch 400 grit disc, which is actually meant for wood. I didn't worry too much about using 400 grit after seeing that the Meguiar's Professional Headlight Restoration Kit includes a 320 grit sanding disc.

Yes I also agree that I misted too much water, and still learning how much water I actually should use. Hmmm I guess I need pass the owner some sealant.

Thanks for your input! Much appreciated. I like previous hair style too, hahaha!

Hey bro, I only found out today that I have missed plenty of your detailing epic. Now slowly scroll abt.. Thanks for sharing, I always manage to learn some tips from your post.

Regarding the abralon sand disc, iirc a foam sanding disc when compare to hand sanding will be milder approximately by 500gr meaning to say hand sanding at 2500gr = foam sanding at 2000gr. If you have the patient to sand up to abralon 4000gr, you may even abolish compounding unless you going for perfection.

Did you throw away those portion that you cut out from your abralon?Actually no need to cut so uniform from the center, you can cut more to the left then you will have a bigger portion on your right. Cut them into square shape and you have make yourself a 2500gr hand sanding strength for spot correction. Sand disc Ex you know, lol..

bro dschia,

Aiyaaa why didn't I think of that, cutting more to the left, ish, cannot think out of the box, too worried cannot restore the headlamps that time, haha. Yeah sanding disc really ex lah.... T.T

Thanks for the hand sanding vs machine sanding gr comparison!

Really great work here!

I admire the work you did. It was tough and time consuming. And I bet it requires a lot of patience, too.

Once my car's Headlight Restoration service was done by Bulls Eye.

Post a Comment